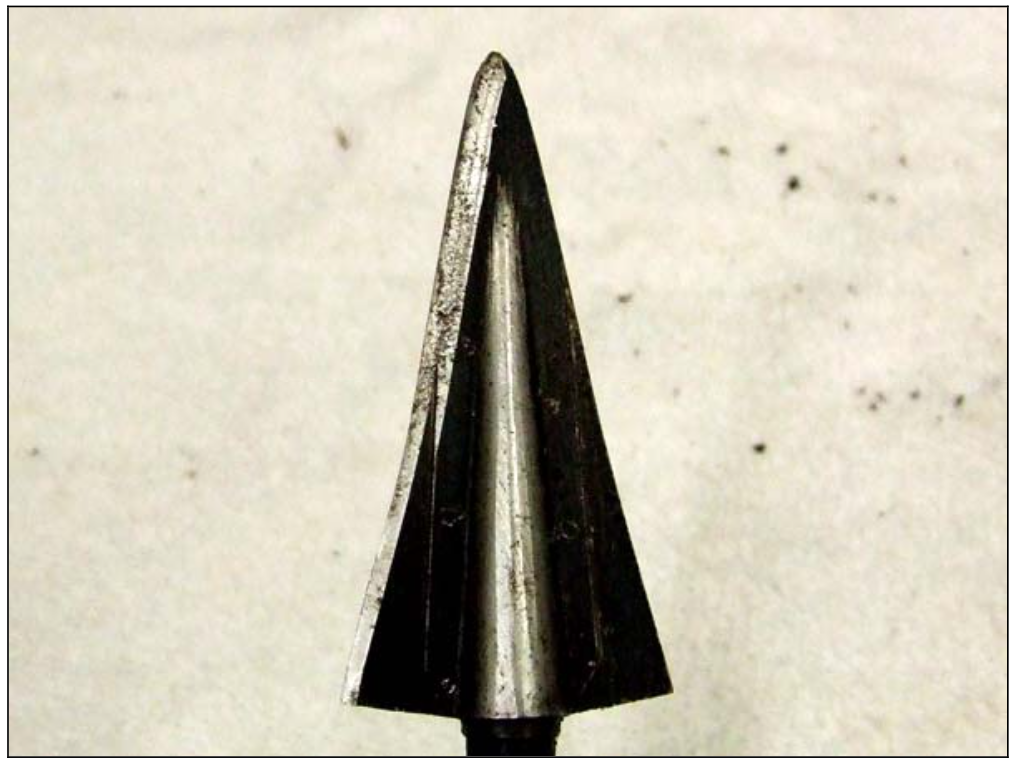

Single-Bevel broadheads are not new to the bowhunting scene. Harry Elburg was the first in modern times to manufacture a single-bevel broadhead, and his original Grizzly hit production some three decades ago. But Harry definitely wasn’t the first to produce a single-bevel broadhead; I’ve seen ancient stone points with single-bevels!

Birth of a legend: The prototype mock-ups of Harry Elburg’s original Grizzly broadhead, made first from cardboard and then sheet-metal. The wide-cut broadhead shown is the Goshawk. Its braised two-piece blade construction provided the inspirational spark, but the Grizzly’s design, with single-bevel edge and Tanto tip profile were all Harry’s. From the Grizzly’s inception, Harry understood the benefits a single-bevel offered, explaining them in detail the first time I talked to him, nearly 30 years ago. Every benefit Harry described has proven correct!

During the last 25 years I’ve intensely studied broadhead design, and how it affects a hunting arrow’s terminal performance in tissues; field testing hundreds of different heads in real tissues, dissecting wound channels and looking at results. It’s taken me that long to fully comprehend the ‘how and why’ of single-bevel broadhead performance, and the numerous and remarkable advantages it offers the bowhunter. The most obvious functional difference between single and double-beveled broadheads is the rotation single-bevels induce as the broadhead penetrates.

Everyone knows that arrows rotate in flight, because of the effect of the fletching. Few, however, give arrow rotation any thought beyond that. And why should they? When using a double- beveled broadhead all arrow rotation stops at impact and, unless the broadhead is deviated in some way by impact with a hard tissue, such as bone, the arrow penetrates straight through an animal without any rotation. Examination of entrance and exit wounds, and the intervening wound channel, confirms this.

During flight the typical arrow makes one complete revolution (360 degrees) in about 60 inches of travel. Several times I’ve measured the rotational rate exhibited for one specific single-bevel broadhead design; the Modified Grizzly. It’s the broadhead I use for most of my hunting. Its single- bevel edges induce one complete revolution in just under 16″ of soft-tissue travel (through ‘pure meat’).

The Modified Grizzly is an altered version of the 190 grain Grizzly El Grande. It is 1″ wide, has a blade length of 3.125″, a 25 degree right-hand single bevel, a 30 degree cut-on-impact Tanto tip, and a main-blade angle of attack of 7.4 degrees. Its finished weight is 170 grains.

Though many people associate the Modified Grizzly with me and the Study, I can’t take credit for its design. If you look at Harry’s paper-prototypes in the photo above you’ll see his conceptual versions; there are three. The two ‘narrow versions’ bear extreme similarity in length, width and profile to the Modified Grizzly and the Grizzly Extreme – the two modifications I commonly make to the production model. And for good reason; all those years ago, when Harry first told me what he felt single-bevels could do, I paid attention to everything he said!

What effect does broadhead rotation have during tissue penetration, and why is it an advantage? There are several advantages, but the most obvious is when the arrow penetrates bone. The bevel-induced rotation tends to cause massive bone breaks; especially in the heavier bone; whereas a double-bevel broadhead simply forces its way directly through, rarely splitting any other than the very lightest of bone. Splitting, rather than piercing bone has demonstrated a major penetration benefit – it lowers drag on the trailing shaft; and test results show that shaft drag is a huge penetration-reducing factor.

Why do single-bevel blades rotate? If you happen to have any kitchen knives with a single-bevel edge, give this a try. While keeping the blade’s width absolutely vertical, try cutting a thin slice off a big roast or ham … or even a sizable chunk of cheese or a big tomato. What happens? The knife blade ‘walks’ to one side; the side opposite the single bevel. The cutting edge is deviated by the pressure the meat (or whatever it is your slicing) is exerting on the blade’s bevel – and which isn’t being off-set by having an even amount of pressure ‘pushing’ on the other side of the blade (the side with no bevel).

If that single-beveled knife blade is shoved directly through a slab of meat, the blade does not pass straight through. As the pressure against the bevel forces the blade’s edge to deviate one direction, the blade’s back-edge is forced against the meat, but in the opposing direction; i.e. as the cut ‘walks right’ the blade’s back edge is forced to the left – and the blade rotates. As the blade rotates, its surface area also exerts pressure on the meat.

Where did that pressure the knife blade exerts on the meat come from? It’s the same pressure the meat applied to the edge- bevel, being transferred back onto the meat. But there’s now a difference in the direction that pressure is being applied; it’s at a right angle to the direction of the knife blade’s passage through the meat. If a similar single-bevel is added on the back of the knife blade, on the opposite side of the blade’s face from the first bevel, the amount of pressure (force) the ’tissue push’ generates against the bevels becomes double what it was when only one edge was single-beveled; and the force the blade- flat exerts against the meat at a right angle to its direction of travel is also doubled.

The source and effect of a single-bevel broadhead’s rotation is being dwelled upon a bit because most people don’t understand it. Most folks appear to believe the single-bevel slices in and pulls the blade to the side. It doesn’t. A single- beveled broadhead’s rotation is caused by the tissue(s) the blade is penetrating. The blade, and its single bevel, pushes against the tissues and the tissues push back (resistance force).

Because the tissue’s ‘push’ on the broadhead’s bevel is not met by any ’tissue push’ on the opposite side of that individual blade’s edge, the edge is shoved sideways; just as the knife’s blade edge was when it made that ‘walking cut’. Since a broadhead is piercing the tissue, and both its edges are being forced sideways (in the same direction) the broadhead rotates as it move forward.

As the broadhead rotates, its face (the blade flat) transmits whatever amount of ‘push’ the tissue generates on the single bevels right back onto the tissue; over a section of tissue equaling one-half of the broadhead’s total surface area, and at a right angle to the direction of arrow penetration. As the broadhead’s entire blade-width is rotated, that ‘right angle pressure’ on the tissue is trying to force the tissue apart. The more force applied between tissue and bevel, the greater the blade’s torque, and the greater the ‘splitting force’.

Succinctly:

1) It is the tissue’s pressure against the bevel which causes the blade to rotate, producing the blade’s torque.

2) The blade-face transmits this force back onto the tissue, but at a right angle to the direction of arrow travel.

3) The less ‘give’ the tissue has, the greater the total pressure generated.

4) The harder the arrow pushes the bevel against the tissue, the harder the tissue’s resistance-force pushes back against the bevel; and the greater the total pressure generated.

5) The thicker the tissue is (up to a thickness equaling the blade’s length), the greater the total amount of bevel-surface that’s in contact with the tissue; and the greater the total pressure generated.

6) The thicker the tissue, the longer the time of contact between bevel and tissue as the blade passes through; and the greater the total force generated.

The forgoing are important concepts in understanding:

1) How and why single-bevel broadheads split bone;

2) Why splits are more common in heavy bones than they are in lighter bones and;

3) Why a broadhead’s ability to penetrate deeply is so important when it’s an extremely heavy bone that needs breaking (and this is where having high broadhead mechanical advantage also becomes a very important factor in creating the bone- split).

The simple explanation is: When an arrow tipped with one of those Modified Grizzly heads passes through a bone, the arrow applies force between the single-bevel’s taper and the bone. The bone applies a firm resistance back onto the bevel. This induces rotation, which exerts torque; a twisting force. The blade face transmits this torque back to the bone, at a right angle to the arrow’s direction of travel. The deeper the broadhead penetrates into the bone, the greater the surface area of bevel that’s in contact with the bone; and the greater the total splitting-force generated. When the total applied lateral pressure exceeds the bone’s tensile strength, bam – the bone splits or breaks.

And the even simpler one is: The bone’s pressure against the Modified Grizzly’s single-bevel tries to rotate (twist) the entire broadhead about 70 degrees during its 3-1/8″ of travel through the bone. This exerts significant lateral pressure. Try sticking even a very thin knife blade through a bone and rotating it just a few degrees; the bone splits big-time, and resistance to penetration drops instantly and dramatically.

Since the tissue pressure on the bevel, which causes the rotation and generates the force used to split the bone, is a result of the arrow’s force applied to the tissue, does this mean arrow force is being used up in order to break the bone? Yes. However, breaking a bone in this manner uses up less arrow force than if the arrow has to push its way directly through the bone. That’s why a single-bevel broadhead consistently shows far more tissue penetration after passing through the bone than a matching, but double-beveled broadhead.

I think one factor is what energy a single-bevel uses, and how it is used when breaking bones. Single-bevel rotation may be tapping into the rotational energy the arrow carries in flight, applying it usefully in breaking bone. A second factor that I think may be important is that rotational velocity (and the resultant rotational force) is shed more slowly than liner velocity. (During flight, a bullet from a rifled barrel sheds rotational velocity more slowly than linear velocity, and is still revolving in tissues after all forward motion has ceased; due to the gyroscopic effect.) Regardless of what portion(s) of the arrow’s kinetic energy the force for splitting bones is derived from, the consistent penetration gain they show over matching broadheads/arrows provides empirical proof that single- bevel broadheads use up less arrow energy and force to breach bones than do matching-profile single-beveled broadheads.

Many who’ve never closely examined the difference a single- bevel can make question that broadhead rotation has much effect. Let’s take a look at just what a single bevel does, in both bone and soft tissues. The following photos show what the single- bevel does, why it works and the results of its many effects during arrow penetration. We’ll begin with their splitting- effect on firm tissues.

This first picture shows the setup I use to demonstrate what happens during double-bevel and single-bevel broadhead penetration. It’s a short section of shaft that’s mounted on a roller-bearing, allowing the arrow to free-rotate as it’s pushed through a target. Fletching was left in place because it allows folks to witness the amount of arrow rotation the single-bevel is causing. The broadhead shown here is a 125 grain, right-hand single-beveled Grizzly.

In order to see the splitting effect, a firm but brittle (prone to fracture) target is best. Things such as foam and paper don’t exert firm enough pressure against the bevel, and tend to be compressed or pushed aside. What’s needed is something substantially solid, so the medium can exert firm pressure against the bevel.

It’s the differing directional pressure exerted onto the bevel by the medium itself that causes the rotation, which, in turn, allows the blade to exert torque onto the object being penetrated. How ‘solid’ that tissue is has an affect on the amount of rotational force generated. The blade’s face transfers whatever amount of force is generated across a large area of the medium, as a laterally-acting force.

In mediums that aren’t firm, or don’t have much force pushing on the bevel, there won’t be as much rotational pressure. In fact, passing through a total vacuum – devoid of matter – there would be no resistance at all on either side of the blade, and a single-bevel won’t cause any rotation whatsoever! The denser the medium penetrated, the greater the rotational pressure and the more torque it generates. When it comes to generating a bevel-induced split, the firmer the tissue being penetrated the better.

Fortunately, suitable test targets for demonstrating bevel- induced rotation aren’t hard to find. I generally like to use something for the ‘target’ that I can eat after I’ve ‘killed it’. The one I prefer is a common potato, though most any firm fruit or vegetable will work, as will most meat and cheese (avoid the trendy brie and camembert, though – they’re way too soft). All the things listed will exhibit the rotation very nicely, and all but the meat will show the splitting effect.

Holding the arrow-setup only by the roller bearing, so the arrow can freely rotate, the broadhead is pushed slowly through the potato. I usually do a double-beveled broadhead first, to show how most commonly used broadheads penetrate a firm, brittle structure.

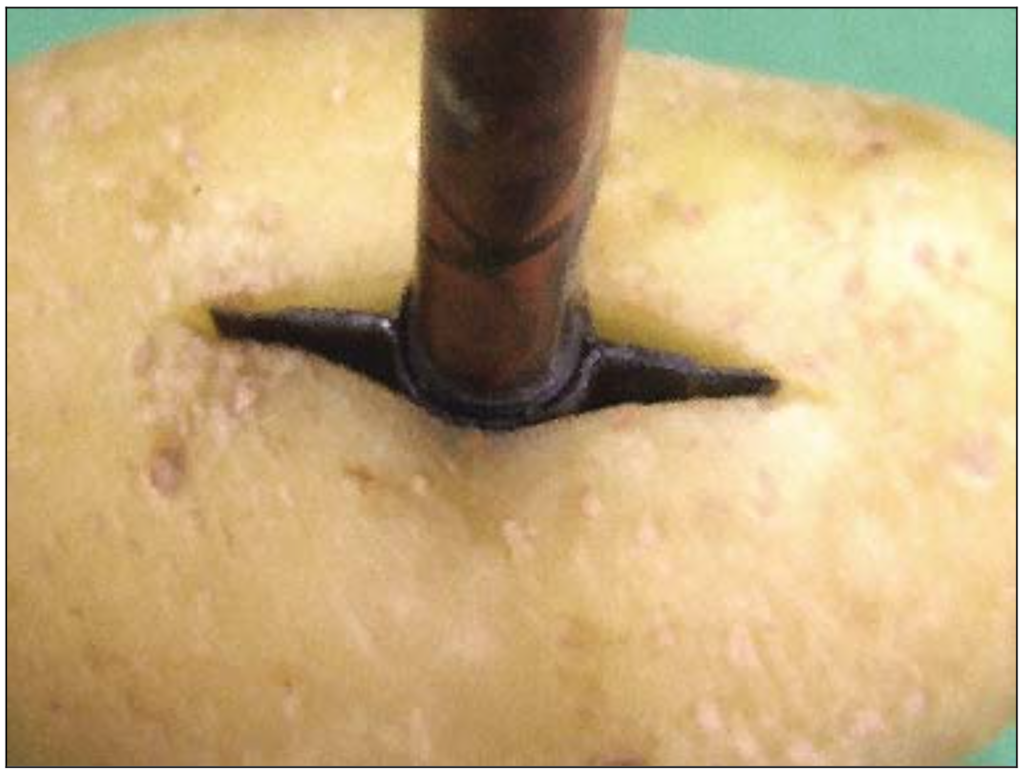

The broadhead shown in Photo 2 is the 189 grain double- beveled Pro Big Game. This one was just pushed into a potato from the side. All it does is make a cut.

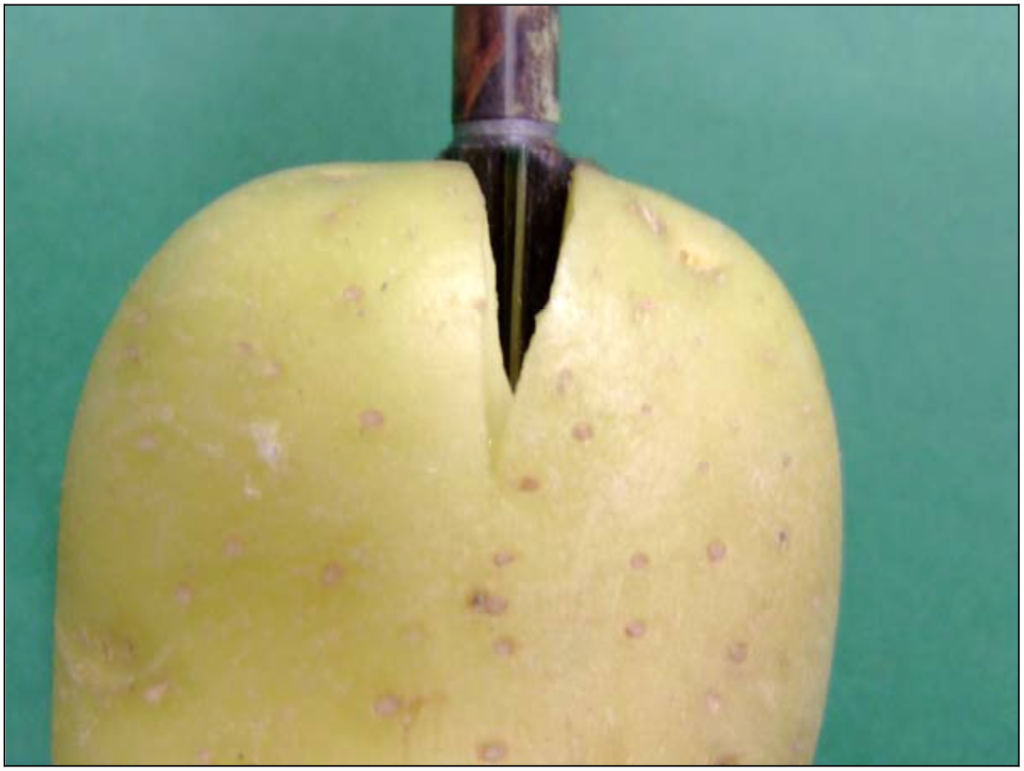

Photo 3 shows the Pro Big Game, mounted on the free-rotating shaft, being pushed lengthwise through a potato about 2 1⁄2″ long. Note the slight split, a result of the ferrule and blade’s wedge-effect. Also note that the blade shows no rotation, in relation to the forming split. At this point, almost a half-inch of the broadhead’s 3″ long blade’s tip is already protruding from the potato’s other end.

Photo 4B

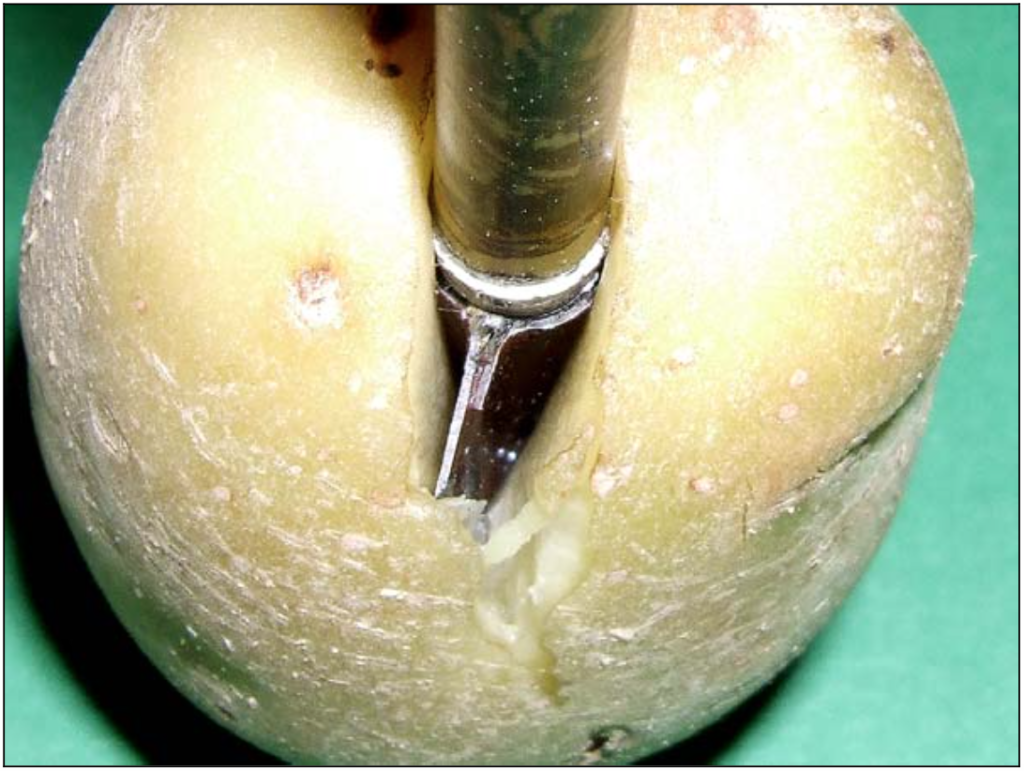

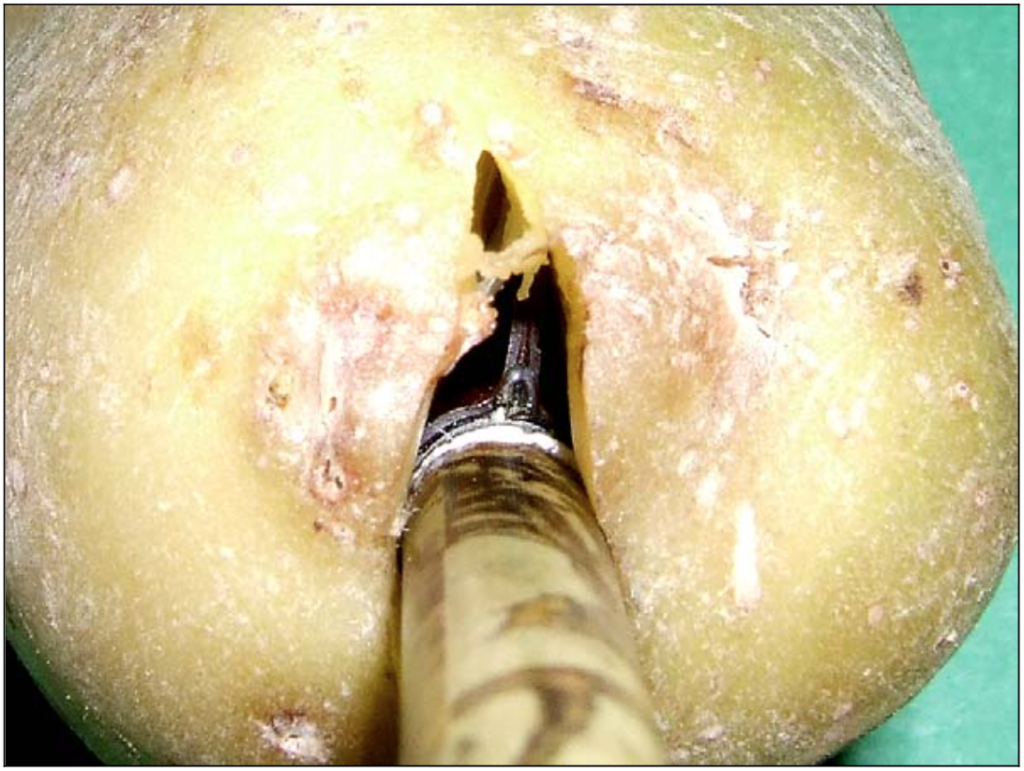

Photos 4A and 4B show the 125 grain Grizzly on the free- rotation setup, being forced through a like-size potato. Note what the blade is doing. The potato’s ’tissue’ is pressing against the blade’s single-bevels, forcing the head to ‘twist’. The broadhead’s blade-face is transmitting that pressure; pushing against opposing sides of the potato’s developing split, forcing the potato’s ‘halves’ away from each other. Note the split beginning to form, already almost half way down the potato. This broadhead is shorter than the Pro Big game, and its tip hasn’t quite reached the other end of the potato yet.

And here’s the routine result of the potato-tests. The smaller, single-beveled Grizzly caused the potato (left) to split completely in two by the time the head’s trailing edge was half way through. Though the larger Pro Big Game (it’s for a 23/64″ shaft) has a 4.2% larger ferrule diameter and a 9.1% wider cut, it passed through without splitting the potato apart, making only small splits at each end. So what does bevel-induced lateral pressure mean when it comes to real bone? Here are some examples.

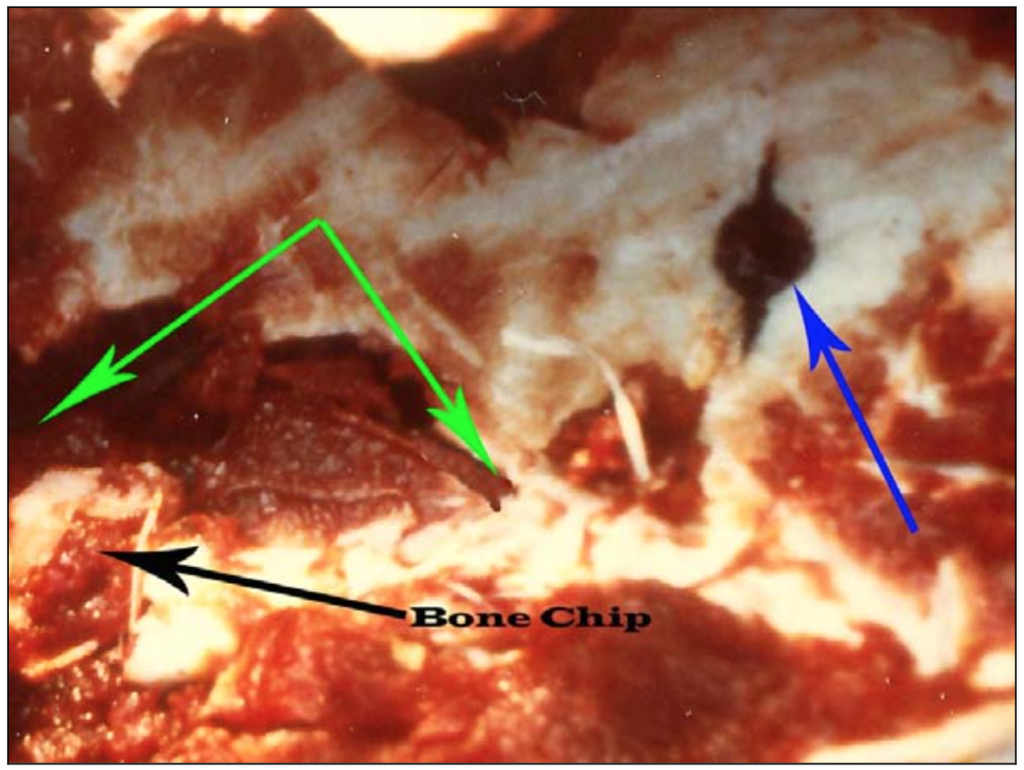

Photo 6 shows a section of heavy zebra scapula that’s been penetrated by both a single and double bevel broadhead having nearly identical dimensions; both have a 1″ cut-width, while one is 3″ long and the other 3.125″. Both arrows are from the same bow and each had the same type shaft, with arrow mass differing by only 10 grains. The double-beveled 160 grain Howard Hill broadhead (blue arrow) punched a neat hole. The single-bevel Modified Grizzly (green arrows – and yes, that’s all one hole) busted a big chunk of bone away (the black arrow is pointing to one big piece of it).

In Photo 6, which of the resulting holes do you think will allow the arrow’s trailing shaft to pass through this scapula most easily? Which arrow do you think used up more of its force during bone penetration? Which will show the greatest overall penetration? The actual outcomes were a thorax-traversing hit for the Modified Grizzly (with exit wound), while the Howard Hill barely lacerated one lung, having hung-up in the on-side rib.

Just as with the potato, the single-beveled broadhead’s ‘twisting force’ created a large break in the bone, early in its penetration. As soon as that happened, CRACK … the bone’s structural integrity was breached and resistance to penetration immediately dropped. The arrow expended less force breaching the bone, retaining more force that it could apply to penetrating underlying tissues. The bigger hole through the bone meant less shaft drag too, saving even more arrow-force for deeper penetration. These are the precise reasons single-bevel broadheads consistently show a substantial gain in average penetration when heavy bone is hit, when compared to identical profile broadheads having double-bevels, and tested side-by-side on identical arrows at the same level of impact force.

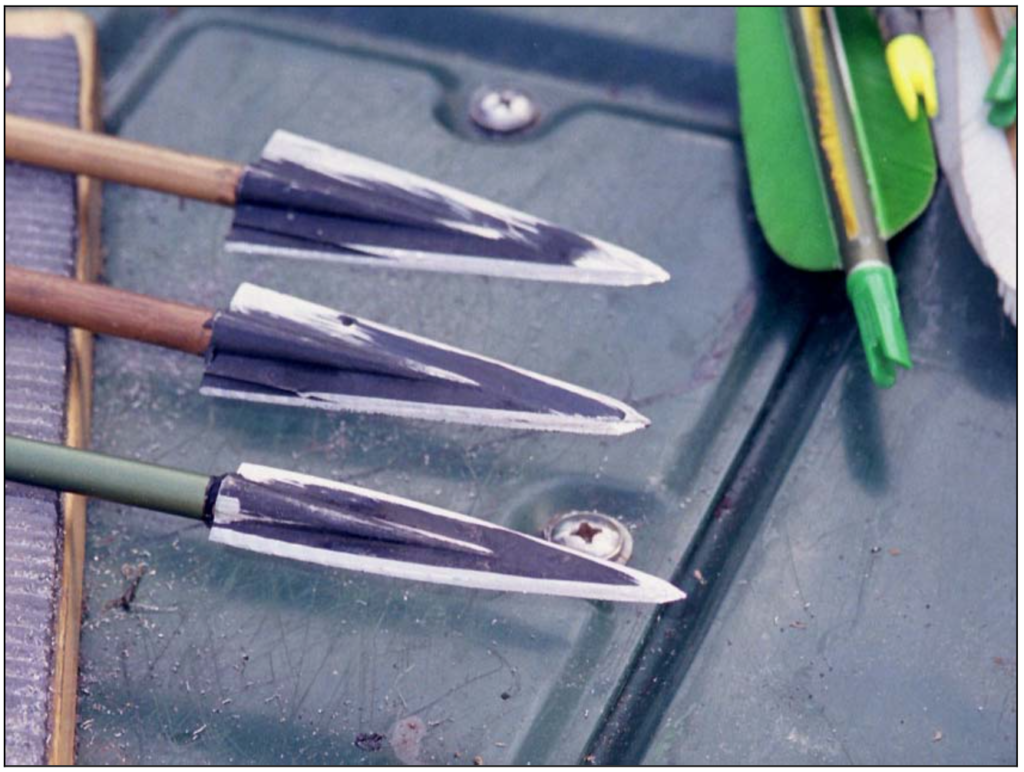

Shown in Photo 7 are the three versions of the 190 grain Grizzly El Grande that I commonly use, both in testing and when hunting. The uppermost one is the standard 190 grain, modified to a COI Tanto tip and with the edge-bevel changed to 25 degrees. In the middle, the Modified Grizzly; 1″ wide, reduced blade-taper and a COI Tanto tip. At the bottom, the Grizzly Extreme; 11/16″ wide, blade taper further reduced, and the COI Tanto tip. These are shown for reference. Note the similarity to Harry’s three original paper mock-ups, shown in the first photo.

Photo 8 is a cleaned and bleached buffalo rib, showing a 4″ bone-split made by the very-narrow, 11/16″ wide Grizzly Extreme.

Here’s the same bone (right) shown with a similar rib through which a very wide, double-beveled Deadhead has passes (left). Note the highly visible bevel-induced rotation shown by the Extreme.

Photo 10 shows the exit side of two buffalo ribs. The one on the right is from the Deadhead shown above. The rib on the left shows the exits of a Modified Grizzly (upper) and the Grizzly Extreme (lower). Such large bone splits are the norm for single-bevel broadheads. Large bone splits are an extremely rare occurrence with any double-beveled broadhead.

In Photo 11 note the rib thickness of mature, trophy-size buffalo bulls. This rib is from a bull killed by Doug Chase. The broadhead is a custom single-bevel STOS, and was used on an Extreme FOC carbon arrow from a 70#@31″ DAS recurve. It also achieved an exit wound, with almost a foot of off-side arrow protrusion.

Photo 12 shows Doug’s left single-bevel STOS, after use on the buffalo.

Here’s the impact-side of the rib shown in Photo 11. There’s a long lengthwise split with a big chunk of rib missing, and a sizable crack completely across the half-inch thick rib! Was this an isolated occurrence?

Not hardly! This is a rib from the other trophy buffalo bull Doug took on the same hunt. Broadhead, arrow setup and bow were the same – as was the outcome; a big rib split with a chunk of bone broken away, and an exit wound with several inches of arrow protruding from it.

If the following photos look familiar, it’s because I’ve used them before. They are among the more dramatic examples of massive bone splits I’ve encountered with single-bevel broadheads, and are most notable because they occurred on extremely heavy scapulas. Most large bone-breaks occur on long bones; ribs, humerus, femur, etcetera – or smaller size, but very dense bones; vertebra and ball-joints. Impacts with flat- bones, like the scapula, more often end up with holes, like that shown in Photo 6, or just S-shaped holes with radiating cracks, like that in Photo 8’s buffalo rib.

The thinner the bone, the less likely you’ll see a massive hole or split. On thin bone you’ll more commonly see small cracks develop around the single-bevel’s hole or radiating from ends of the S-cut. These tiny cracks relieve the torque pressure before a major ‘blow-out’ can occur. They not only relieve pressure on the bone, they also relieve bone pressure against the broadhead and shaft, allowing easier penetration. The pressure reduction from small cracks may not be as great as it would be with a large break, but it still represents a very significant reduction in penetration-resistance.

The thin-bone cracks are common because lighter, thinner bones induce ‘less push’ against the single-bevel, producing a slower developing and less forceful torque than thicker, heavier bones. The heavier the bone the more likely it is to split or snap rather than develop small, pressure-relieving cracks. Single-bevel edges become more important, and more effective, as the bone becomes thicker.

Shown in Photo 15 is the scapula from the largest zebra stallion I’ve ever taken. It’s just over 5/8″ thick. No hole here; a very big chunk of the scapula was split away by the Modified Grizzly.

This is as good as it gets. Photo 16 shows the scapula from a record-class wildebeest bull. Only those who have hunted and taken them can fully appreciate how tough and heavily built a big wildebeest bull is! Pound for pound they are far tougher than buffalo, and their shoulder bones are more than the equal of any elk or moose. The point of arrow impact is indicated by the blue arrow. Note not only the extent of the bone split, but the multiple large chunks of bone broken away. This was also the result of a 1″ wide Modified Grizzly.

A point worth noting is that the surface area of the broadhead’s face (the blade-flat) has an effect on bone splits too, but there are many trade-offs. The greater the surface area of the broadhead’s face, the faster forming and larger the bone split will be – if it occurs. That’s because the blade’s surface area transmits the bevel-induced torque across a larger area of the bone … and that’s where the trade-offs begin.

To split any given bone, a specific level of force must be applied per given square area of the bone. If the blade’s surface area is too great, the level of bevel-induced torque force may become too dissipated (spread over too large an area) to be of sufficient strength to cause a bone break.

A bigger broadhead requires more ‘raw force’ to penetrate the bone. Remember that the rotation, and its associated torque force, depends on the angle and surface area of the bevel that’s in contact with the bone; not the blade’s surface area in contact. For maximum bone splitting effect the goal is to have, at any given instant, as much bevel area as possible in contact with the bone; in relation to the amount of blade surface area in contact. The key is to balance the amount of torque force the bevel can generate with the amount of blade surface area being used to transmit that force to the bone. It’s because of this ‘balance’ that my favorite broadhead design is the Modified Grizzly. Outcomes indicate it causes big bone breaks more frequently then either the 190 Grizzly or the Grizzly Extreme; it has demonstrated better balance at the arrow-force levels I commonly use in my hunting.

*Stay tuned for part 2 in our April 2016 Issue

About the Author:

Dr. Ed Ashby invested 27 years in the study of arrow performance and broadhead lethality. His testing is the closest thing to the scientific method as is possible under field-testing conditions. Never before has anyone tested arrow and broadheads on actual game animals on such a scale. The test results have been carefully compiled and are now available to the public free of charge at Alaska Bowhunting Supply.

Bowhunters everywhere owe Dr. Ashby a debt of gratitude as his data reveals which broadheads and arrows perform the best on real game animals. The results show that whether you shoot a traditional bow like a recurve or longbow, or a compound, the arrows and broadheads that performed well in testing, will perform for you where it matters most, in the field.

His goal is to educate the world on what kinds of arrows and broadheads best penetrate big game animals. He receives no compensation for any of his research but shares the results freely. He wants to educate bowhunters everywhere on what works best on big game animals so the animals may be harvested in the most efficient manner possible.