I have been on the hunt for the ideal boot for many years now. I have tested countless models in a wide array of conditions and environments and have been, time and time again, disappointed by most “innovations” in boot design and functionality. In this article, I hope to help you sift through all the technical language and marketing speak endemic to the footwear industry and drill down on the truly essential components of a well built, high-performing, mountain applicable hunting boot that will serve you well in the backcountry.

These days it can be tough to determine exactly what you need in a boot. With the proliferation of the ultralight movement, boot manufacturers seem to be in a constant process of updating current models, introducing new models and announcing innovations that supposedly make boots better than ever before.

With the endless stream of buzzwords, technical jargon, and fancy Himalayan model names conjuring up visions of wind swept peaks in remote, far-flung corners of the globe, most manufacturers seem to be highly focused on their bark, but what about their actual bite.

The truth is, newer and lighter is not always better. Am I anti-innovation? Hell no. Am I anti-unproven and un-tested? Absolutely. In my opinion, a single season of hunting a single species does not constitute a realistic test of a boot’s ultimate performance and durability. Unless of course that single season, or even single hunt, produces an outright product failure. That failure, my esteemed reader, is undoubtedly a fair test of a boot’s inability to perform.

As a specific example, I recently purchased a well-known lightweight mountain boot from a well-known European manufacturer to take on my February goat hunt. I thought I’d tested it sufficiently in the weeks prior to the hunt and went in confident I had the right boot for the job. On returning home, the lacing system had failed and the sole was already showing significant wear and tear. This was a five-day hunt! When I took the boots back, the retailer told me this was normal for this model of boot and it wasn’t designed to handle the stresses I’d placed on it. That’s right, a $400+ “mountain boot” apparently wasn’t designed to handle five days in the mountains. I promptly asked for my money back and thankfully the retailer agreed. Needless to say, my continued skepticism surrounding the footwear industry increased a few more notches after this experience.

The difficult truth however, is a high-performing, well-built, dependable and durable mountain hunting boot is not easy to build. The forces it must contend with and the environments it must perform within are varied, highly challenging, and often brutally unforgiving. Compound these issues with the intricacies of the human foot and I can more than appreciate the difficulty faced in designing and building a mountain hunting boot that comfortably performs across a variety of use-case scenarios and lasts long enough to be worth the expenditure.

Nonetheless, boots are without question one of, if not the, most critical decision a hunter will face in any given year. Your hunting environment, hunting style, foot type, physical preparation, injury history and budget all play pivotal roles in what is arguably the most critical piece of gear you will ever buy. With countless brands, models and retailers to sift through, finding the right boot can be an arduous, frustrating and expensive task.

There is no singular answer. Every foot is different, even your own two feet can differ drastically in shape, function and footwear needs. That said, there are certain characteristics to look for in a boot that will significantly increase your chances of locating a boot you can trust to suit your needs.

In my experience, the best starting point is to focus on manufacturers that have been in the mountain footwear game for a long time and with models that, year after year, remain in their inventory. Underperforming boots don’t survive the people’s court for long. The footwear industry is rife with examples of “innovative” boots or shoes that can’t be found twelve months after they were introduced to the market.

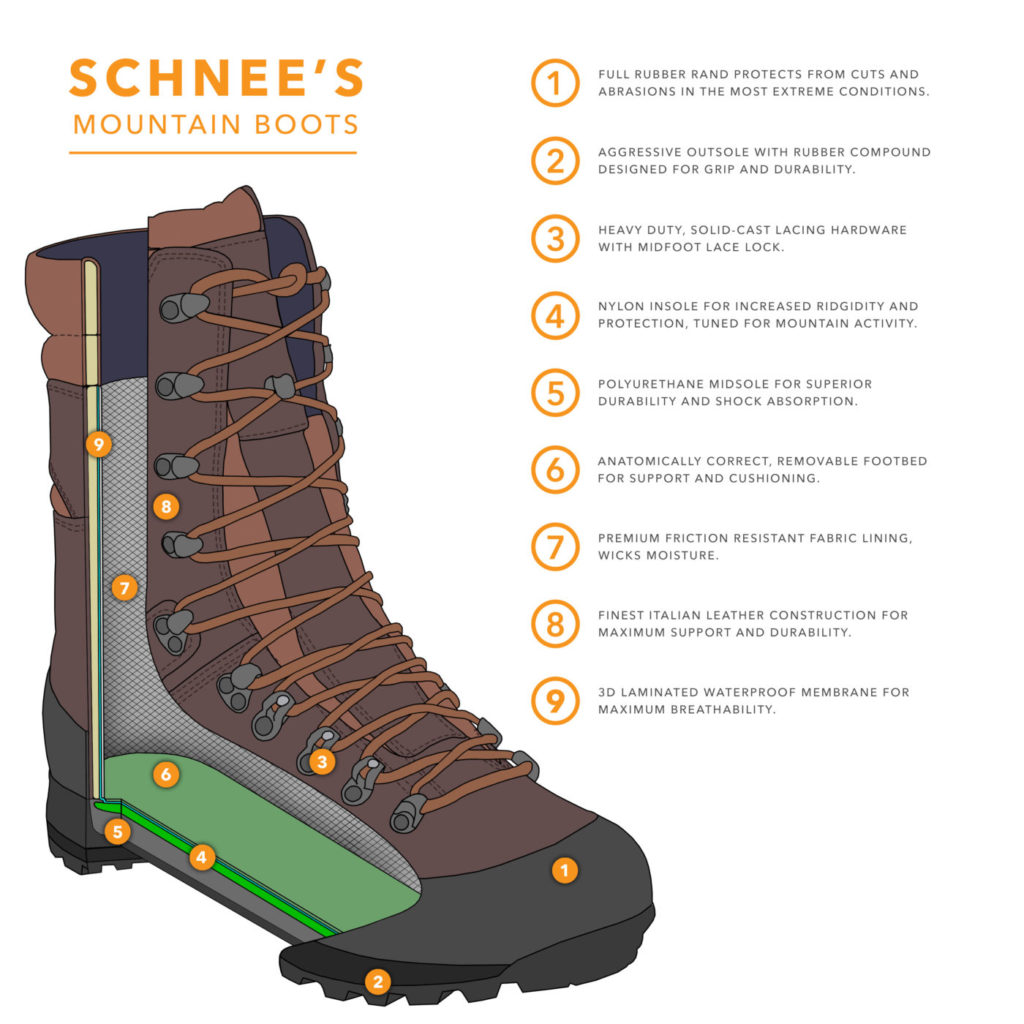

Going one step further (pun fully intended), it’s always best to turn to brands that are accustomed to meeting the demands faced by the mountain hunter. Unfortunately, this list is incredibly small. I turned to our friends at Schnee’s to help us dissect what goes into one of their perennially top-performing boots, the Granite so that we could get a better understanding of what goes into a durable, mountain-centric hunting boot and why.

Schnee’s has been building mountain hunting boots for decades. Their boots have been tested in some of the harshest hunting environments imaginable. From legendary pac boots to mountain boots trusted by premiere mountain guides the world over, they have been in the game long enough to know what works and what doesn’t.

With that in mind, let’s dissect the Granite 4 and delve into the key components of a boot that will perform, endure and keep you hunting hard year in and year out. (Scroll down beneath the image to read my notes on the components emphasized in the Granite 4 diagram.)

1) Full Rubber Rand:

This one’s a no-brainer. Can you get away with nothing more than a toe-cap? In some cases, yes. But for true mountain hunting that finds you above timberline, a full rubber rand will protect the upper and significantly increase the longevity of your boots.

2) Aggressive Outsole Made from Mountain Worthy Rubber:

We’ve all been there. Slick shale, boulders and downed timber are the norm not the exception when it comes to mountain hunting. Many of the mainstream boot manufacturers, especially the European brands, use rubber compounds that are built for durability and grip in dry conditions (think summer tourist season). Here in North America, hunting season often finds us traversing terrain that is wet with rain or snow. Your outsole must handle both dry and wet conditions. I can’t even begin to tell you the number of times I’ve found myself doing the hockey skate dance on wet or slick terrain or when crossing streams and rivers while wearing a boot that was clearly not designed to provide traction in these situations. To solve this issue, Schnee’s utilizes a proprietary rubber compound that places equal emphasis on dry and wet footing while not sacrificing durability.

3) Solid Cast Lacing Hardware with Lace Lock:

Simply put, if your lacing system fails you may as well go home. The fit and support provided by a boot is heavily dependent on the lacing system. A rigid sole is worthless without a stable upper that keeps your foot secure on top of it. I like my boots tight so that I can “feel” the terrain and have personally broken the lacing hardware on numerous boots just lacing them up in the morning before training hikes. Thankfully, this has never occurred on an actual hunt. The midfoot lock is also critical in achieving the right balance of fit, support and comfort for each unique foot and will often be the primary factor in achieving the perfect fit you’re looking for. Lacing hardware is probably one of the most overlooked components in a boot but without question one of the most critical characteristics that separates the premium boots from the rest of the herd.

4) Nylon Insole:

Nylon is renowned for its strength to weight performance and responsiveness. Yes, carbon fiber is more rigid and responsive but having worked with carbon fiber for years in the custom orthotics world I can assure you it is not the magic material it’s often claimed to be. Plus, anything built with carbon fiber is going to cost the manufacturer and therefore the customer far more than nylon. When it comes to the best blend of performance, protection, ground feel, weight and cost, nylon is the material of choice for quality boot builders.

5) Polyurethane Midsole:

You know those running shoes you replace every eight to twelve months? Their midsoles are almost always built with EVA. EVA absorbs shock incredibly well but that “plushness” comes at a significant durability cost. Polyurethane, or PU as its often referenced, loses a little in shock absorption but will last far longer than EVA and stretch your hard-earned dollar over many seasons.

6) Anatomically Correct Removable Footbeds:

Supportive mountain boots need some form of a “buffer” between your foot and the midsole, otherwise your feet would never handle multiple days roaming the backcountry. There are a lot of fancy names and supposed technologies built into factory footbeds but at the end of the day they should match basic foot anatomy and be removable so that if you need to add OTC (over-the-counter) insoles or custom orthotics you can do so without throwing boot fit out the window.

7) Premium Moisture Wicking Fabric Liners:

There are roughly 250,000 sweat glands in the feet. Just smell an old pair of boots or runners if you doubt me. This biological fact produces a very moist environment, especially when you add in the waterproof membranes most of us want in our hunting boots. The liners of a mountain hunting boot must address and manage this moisture. There are numerous leather lined boots on the market today styled after the mountain boots our forefathers would have worn afield. These will produce a quasi-custom fit more readily than synthetic fabrics but will simply not address the guaranteed internal moisture issues we face when exerting ourselves in the mountains.

8) Italian Leather Uppers:

Despite the proliferation of synthetic uppers these days, especially in so-called lightweight boots there is simply no contest between a leather and synthetic upper. Synthetic uppers do not stretch or form as easily as leather, can seldom be treated and repaired and rarely last more than a season of hard mountain hunting. There’s a time and a place for synthetic uppers but there’s a reason most of the mountain hunting dedicated boots you’ll find on the market look very similar year in and year out. Once broken in, a premium leather boot will fit like a glove and provide years of support and durability.

9) 3D Laminated Waterproof Membranes:

Oh, the membrane wars. As we all know there is no shortage of discussion around waterproof membranes, whether we’re talking apparel or footwear. Effective waterproofing can only be achieved through full 3D lamination of the body part in question. Seams, junctures and segmented laminates will fail at some point, especially in the high-stress environment of a boot. Waterproofing must also be balanced with breathability. As mentioned above, the internal boot environment is naturally going to encounter moisture. If the boot is so waterproof that your feet are soaking within an hour of hiking you’re in trouble. Pay careful attention to both the waterproof and breathability ratings provided by the membrane manufacturer.

I hope this article delivered some guidance on what goes into a purpose-built mountain hunting boot and why. With the amount of information available online today, it can be difficult to sift through all that material and conjecture to determine what truly matters for you and your specific needs. Which brings me to my final point.

Building a quality boot is no small endeavor, but there is an additional challenge: properly fitting these boots to your feet. When it comes to making the proper boot decision, narrowing the options down to a selection of well-built, high-performing boots that suit your hunting needs is only step one. The next priority is getting that boot to fit your feet and comfortably perform in the backcountry. Bootfitting is part art and science. A skill that is only learned through years of experience working with all kinds of feet and all kinds of scenarios. But this complex topic is best saved for another article. Stay tuned!