I’ll be the first to admit that getting started in reloading can seem daunting if you’ve never done it or been around it. Try not be discouraged if you haven’t got the full grasp on how it works or if you don’t know exactly what you need. It’s easier than it seems and there are a couple ways to get you into the game.

The quickest and easiest way to get started is to jump in headfirst and just buy a reloading kit from RCBS, Lee, Hornady, or Lyman. The kits will provide most of the essentials, with the exception of the dies and shell holders, because those are caliber-specific.

Once you have your dies and the components, the instructions should have you cranking out ammo instead of making return trips to the reloading store for those little things you forgot to get or didn’t even know you needed. The drawback to kits is that you don’t get to hand pick each and every tool and there’s a good chance you’ll outgrow your kit components at some point.

If you don’t think the kit route is right for you, then you’ve got a lot more homework and research to do. That’s not to suggest it can’t be done in an entirely DIY fashion, it just entails more work. In this series of articles, I’m going to be discussing a variety of reloading topics that will detail many of the techniques and tools used to produce custom, high-precision ammunition for your hunting rifle. Here’s a basic overview of the items that a well-equipped reloading bench might include.

Reloading Manual

Pick up a reloading manual and familiarize yourself with the basics. Lee, Berger, Hornady, Lyman, and Nosler all publish good reloading guides. A manual is your first data source for starting loads, and most of these books provide some basic reloading instruction along with the load “recipes”.

You can also get reliable load data from a variety of internet resources. For newer powders and calibers, the manufacturer websites often provide the most current load information. I always cross-reference the powder manufacturer’s website and compare their loads with published loads from at least one more source. Alliant, Hodgdon, IMR, Winchester, Vihtavuori, and Norma distribute most of the smokeless powders you would use for common big game cartridges. Some of the bullet manufacturers like Nosler also provide data online.

Caliber-specific, mini reloading manuals called “Loadbooks” can also be purchased from Midway USA for many common cartridges. These books compile load data from several sources into a single reference for a given caliber so they provide a broad cross-section of data that you wouldn’t get with a single manual.

Reloading Press

For novices and precision reloaders, I recommend a single-stage press to keep things simple and more precise. Select a good sturdy press with a cast-iron frame and an opening sized sufficiently to load the largest cartridge you plan to shoot/load (don’t forget your buddies). The structural engineer in me prefers the “O”-shaped presses. The RCBS Rock Chucker is probably one of the best-selling presses of all time; the Redding Boss & Big Boss II are highly regarded; and even the value-minded Lee presses will produce precision ammo.

I personally use a Forster Co-Ax single-stage press. It’s a unique design that is highly regarded by precision shooters for producing concentric ammo with minimal runout. If you’re a pistol shooter or high volume shooter of any kind, then upgrading to a turret or progressive press is a good option that will save you a lot of time once you learn the ropes.

Reloading Dies

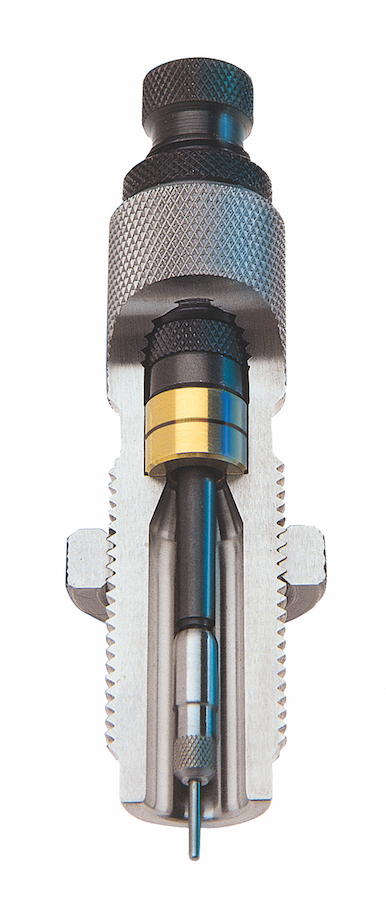

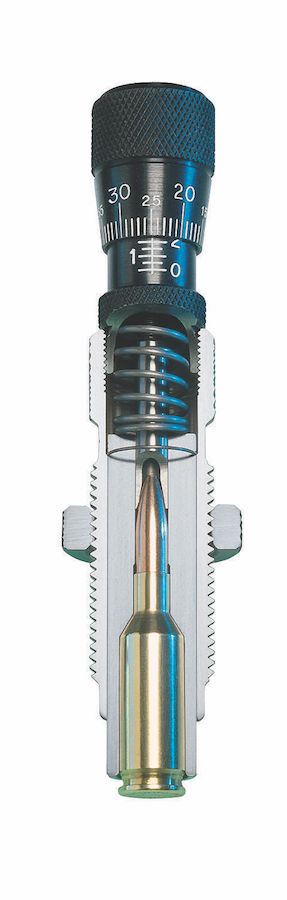

You’ll always have at least two dies – a sizing die and a seating die. The typical, full-length sizing die performs multiple sizing functions at once, but it can also be separated out into more specific single function dies for more flexibility and finer sizing control.

A standard sizing die consists of an inner diameter shaped like your rifle chamber, only slightly smaller. A decapping (de-priming) rod with a neck sizing button threaded about halfway down its length is suspended in the center of the hollow die chamber.

As the die accepts the cartridge, the decapping rod and sizing button pass through the case neck without touching until just before the spent primer is contacted and pushed out. As the primer is pushed out, the cartridge neck and body diameters get squeezed down slightly by the chamber-shape of the die. At the end of the die’s stroke, the case shoulder is also “bumped” or “set back” a few thousandths to ensure the cartridge will chamber and headspace properly.

After the die is bottomed out and the case neck and body are sized down, the case is then pulled back out of the die, which pulls the sizing button back through the newly compressed case neck. As it passes through, the sizing button expands the neck back up to the appropriate dimension to hold a new bullet.

Die sets can range wildly in cost from $30 to $300 or more. Competition style die sets with single function bushing dies and micrometer adjustable seating dies are the most expensive variety, but they can be worth it depending on your accuracy goals. I recommend buying dies in sets, because that generally saves some money and ensures you have matched components designed to work together.

Dies with interchangeable neck bushings or die sets with a separate neck-only sizing die offer better control of the neck diameter. Neck-only sizing dies allow the shooter to size the neck without sizing the body or bumping the shoulder so the fire-formed cartridge still fits the chamber perfectly. These are a favorite of benchrest shooters.

After a few firings, cases that have been neck sized only will need to be fully resized or they will not chamber properly. Neck-only sizing is only appropriate for bolt-action rifles and single shots because autoloaders and lever guns require more clearance to function properly.

Powder Scale

You’ll need some type of a scale for weighing powder charges. There are balance beam scales and electronic scales available, as well as automated powder dispensing scales that will dispense weighed powder charges for you like the RCBS ChargeMaster 1500. The electronic powder dispensers are expensive, but they can sure cut down on the amount of time it takes to trickle out accurate charges. You’ll also need a caliber-specific funnel to get the powder from the pan into your case neck.

If you don’t utilize an electronic dispenser, a powder measure can be used to “throw” fairly accurate charges, and a powder trickler will allow you to trickle powder in the remaining small increments onto the scale to hit your desired weight.

Priming Tool

For precision reloaders and long-range shooters, I recommend using a handheld priming tool. You just can’t replace the “feel” aspect of properly seating a primer with an auto-priming press attachment. RCBS, Lee, and Lyman make good, value-minded priming tools, while Sinclair, K&M, and 21st Century make precision billet hand priming tools that generally cost 2 – 4 times more.

Measuring Tools

A decent set of dial or electronic calipers is essential to measure brass at various stages of the reloading process. Other tools like Hornady’s Headspace and Bullet Comparator tools that attach to the caliper will allow you to accurately measure the length of your loaded rounds and properly gage shoulder bump and headspace using your caliper. Neck wall gauges and concentricity gauges can give you an idea of the consistency of your brass and the quality of your loaded rounds.

Case Prep Tools

These are the hand tools you’ll use to chamfer and deburr the case mouth, clean the neck, clean the residue from the primer pockets, and deburr the flash hole. Lyman sells a nice set of case prep tools in a convenient case to keep them organized.

Case Lube

Before sizing your cases, you have to lube them with a reloading-specific case lube. Don’t try to use anything else or you’ll stick a case in your die. My favorite is Imperial Die Wax. You can use Imperial Dry Lube to lube the inside of the case neck, but always use a wax or other wet lube like Hornady’s One Shot aerosol spray lube for the outside of the case.

Reloading Trays and Ammo Boxes

You’ll need a reloading tray to keep cases upright as you process them. Inexpensive universal trays that will accept a number of different cartridge base dimensions are available from RCBS. Once you get the cartridges loaded, you’ll want to label them and store them in a nice plastic ammo box. I like the 100 and 50-round cases best, but the 20-round plastic cases travel better to save space. Purchase several extra ammo boxes so you can keep different loads organized when you’re testing or if you want to load different bullets for different purposes.

Tumbler

A vibratory or rotary tumbler will shine up your brass cases inside and out and make them look new. I like to tumble my brass before sizing to help remove firing residues and dirt that make a case more likely to stick. I don’t think a tumbler is a necessary item, but shiny cases look better and will size smoother. Basic tumblers are fairly inexpensive. Corn cob tumbling media produces good results for me.

Ultrasonic Case Cleaner

The secret to getting this one past your wife is to tell her you got it to clean her jewelry! These do a nice job of removing hard-to-clean primer pockets and powder residue from inside the cases. They also do a good job of “washing” off case lubes. I like to run my cases through an ultrasonic hot bath after they’re sized and prepped. It’s the last step before I load them. Again, this is not a must-have, but after you’ve spent enough time cleaning primer pockets with the little wire brush primer pocket cleaner, you’ll be more than happy to drop $100 on one of these handy units. I’ve used the RCBS unit with good results.

Case Trimmer

Every time your cases are fired and resized, they will grow a little bit longer. Eventually, the brass will need to be trimmed or it will interfere with the end of the chamber. Keeping brass trimmed to a consistent length improves accuracy and also eliminates safety issues if the cases get too long and the neck bottoms out at the end of the chamber. It’s probably not an item you need until you have a few loadings on your cases, but measure your cases and ensure they are shorter than the maximum allowable length for your cartridge. Better yet, measure your actual chamber length and trim all of your cases equally, cutting them at least .010” short of the chamber’s dimension.

Log Book

If you’re going to succeed as a reloader, you must keep meticulous notes, both at the reloading bench and at the rifle range. Use a fine-point Sharpie to label each batch of test loads so that every shot you take will be a useful data point for testing. The better your notes are, the easier it will be to interpret your results and make good decisions based on exactly how the rifle and ammunition perform at the range.

Components

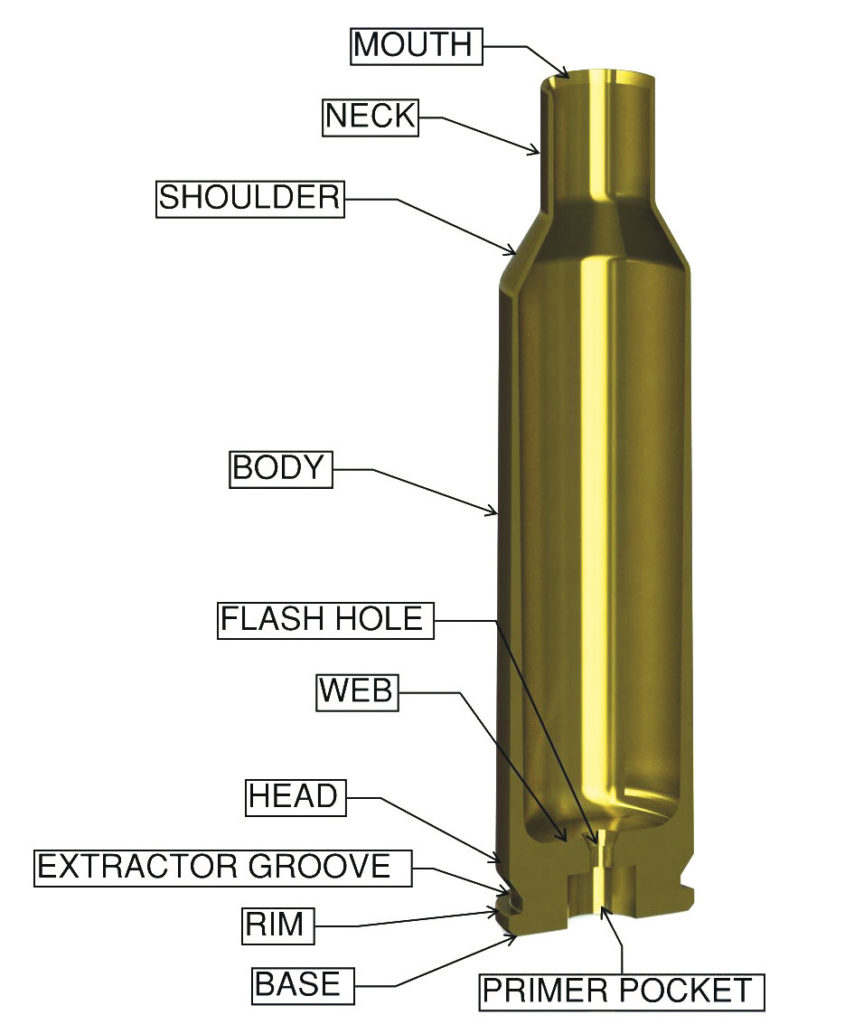

Brass: You need quality ingredients to bake a great cookie, and brass (at nearly $3 per case) is the most important and most expensive component for larger magnums. The good news is that your cases should last you many, many loadings before giving up on you. If you can load them ten times, then that $2.85 Lapua .338 mag. case only costs you 28 cents per loading, which is more in line with the cost of the powder charge you dump into it.

I recommend purchasing high-quality brass if precision is your game. Lapua and Norma are well renowned for producing the best of the best, but Oregon-based Nosler is also offering high-quality, “ready-to-load” brass that I’ve personally used with excellent results.

Winchester, Remington, and other domestics also make quality brass, but you might need to spend a little more time uniforming and prepping it to get it to shoot as well as the high-dollar stuff. The brass and all the work you put into it lays the foundation for your ammunition’s accuracy. It’s like the blueprinted block of a high-performance engine.

Bullet: A lot of factors go into selecting a bullet. First, consider what you’re hunting and select a bullet heavy enough to do the job and then some. Most hunting bullet manufacturers provide recommendations for the type of game their bullets are intended to take.

If you’re a long-range shooter, select a bullet with a high ballistic coefficient and make sure your barrel’s twist rate will stabilize it under all anticipated conditions. Do your homework and read some reviews.

Make sure the bullet is capable of very good accuracy and has performed well on the type of game you’re going after. Finally, be prepared to test a couple to see which your rifle prefers. This is the business end of the cartridge, so don’t skimp here to save money. Likewise, don’t shoot a bullet unsuitable for game just because it shoots well. An animal that is solidly hit and lost with an unsuitable target bullet is far worse than one cleanly missed with a hunting design.

Powder: Check your load data for powders that are shown consistently for the bullet weight you intend to shoot. Often, the powders that show up on every chart are known top-performers.

Next, try to select a temperature insensitive, double-based powder. These powders minimize changes in burn rate relative to temperature fluctuations. This is critical for making sure your loads will shoot consistently under all hunting conditions and also for making sure that velocity fluctuation due to temperature doesn’t cause you to miss at longer ranges. Hodgdon Extreme Powders, IMR Induron powders, and Alliant’s temperature stable Reloader powders are some of the best choices.

Do some internet homework and see which ones are working best for guys shooting your caliber and bullet weight. If you have a custom rifle, definitely talk to the gunsmith and see what he recommends. This is often a good way to narrow down your choices.

Primer: Most guys tend to think that match or benchrest primers are a little more consistent than standard. For the extra $5-$10 per 1000, I usually go ahead and buy match grade. Changing primers doesn’t typically cause big changes in 100 to 300-yard groups, but changing primers can sometimes reduce velocity spread and therefore tighten up long-range vertical groups.

Get Started; More to Come

As you can see, there’s a LOT involved in reloading! The best advice I can give you is simply, get started now and don’t be afraid to take the kit route to get your feet wet.

Regardless of which route you take, you can always sell or hand down items you outgrow, so it’s hard to go wrong. You can’t replace the experience, knowledge, performance, peace of mind, and pride you’ll have when you take full control over your rifle’s accuracy and ammunition supply.

Stay tuned for Part 2 of our Reloading Series, when we’ll discuss developing an accurate load.

RESOURCES

www.nosler.com

www.bergerbullets.com

www.hornady.com

www.leeprecision.com

www.rcbs.com

www.lymanproducts.com

www.alliantpowder.com

www.hodgdonreloading.com

www.imrpowder.com

www.vihtavuori.com

www.sinclairintl.com

www.midwayusa.com